The post bed machine 860 was specially designed to efficiently topstitch side seams in jeans and casual trousers. It is unbeatable as single and twin needle machine.

860 | With powerfull feeding system for topstitching side seams in jeans and casual trousers

As single or double needle with perfect stitch pattern

Your benefits at a glance

Triple feed - suitable for any fabric thickness bottom feed, needle feed and alternating foot-top feed

Triple feed - suitable for any fabric thickness bottom feed, needle feed and alternating foot-top feed

Perfect transport

With the triple feed and available sewing attachments, you can easily sew light chinos/light fabrics and heavy jeans or work trousers.

Optimal climbing qualities

Optimal climbing qualitiesExcellent climbing qualities

Especially when topstitching the side seam, you will come across dividing seams such as the pocket opening and yoke. This is where the switchable 2nd presser foot stroke is invaluable for convincing quality.

Support table with edge guide for efficient working without previous marking for seam lengths up to 200 mm

Support table with edge guide for efficient working without previous marking for seam lengths up to 200 mmOptimal shape

When designing the machine, special attention was paid to the ergonomic handling of the operator.The result is a sewing support element that is perfectly suited for this operation.Loading and correct positioning of the fabric could not be easier.

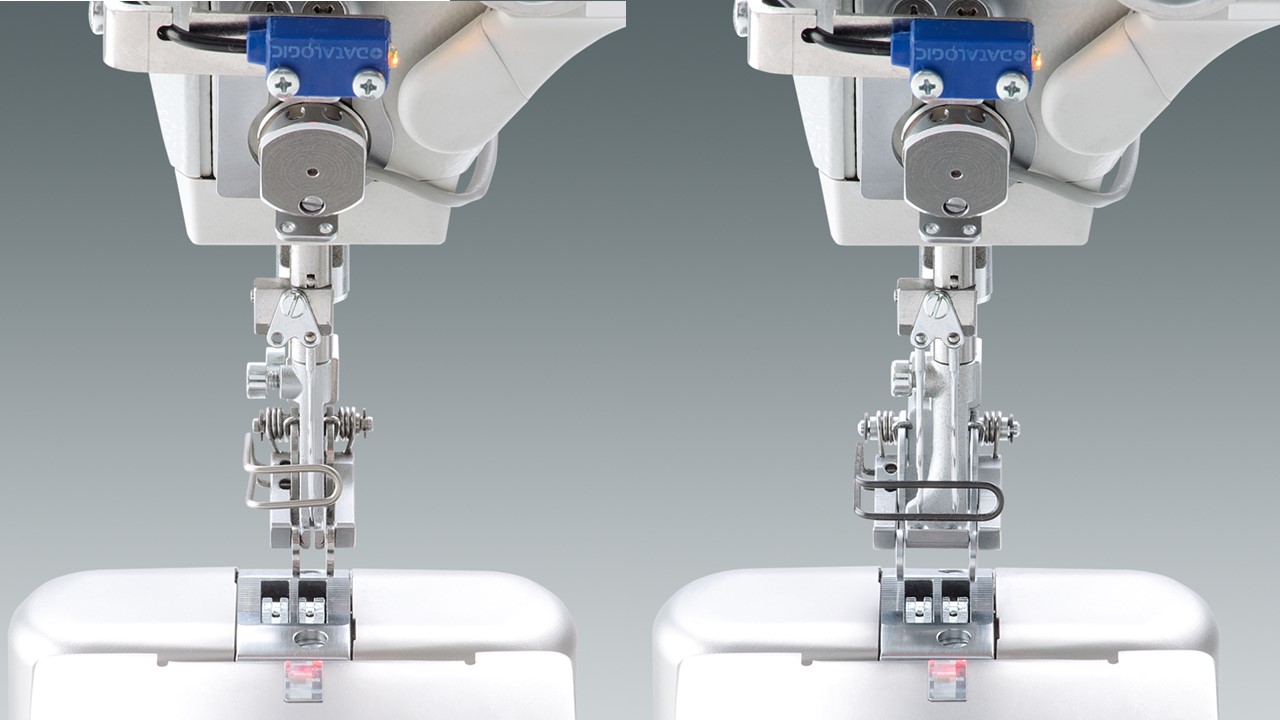

Easy change from 2- to 1- needle

Easy change from 2- to 1- needleEasy conversion

A special asymmetric sewing unit allows a special conversion from two to one needle.Thanks to an asymmetric presser foot for two-needle applications and a symmetric presser foot for single-needle applications, both double and single seams can be sewn only for two-needle machine.

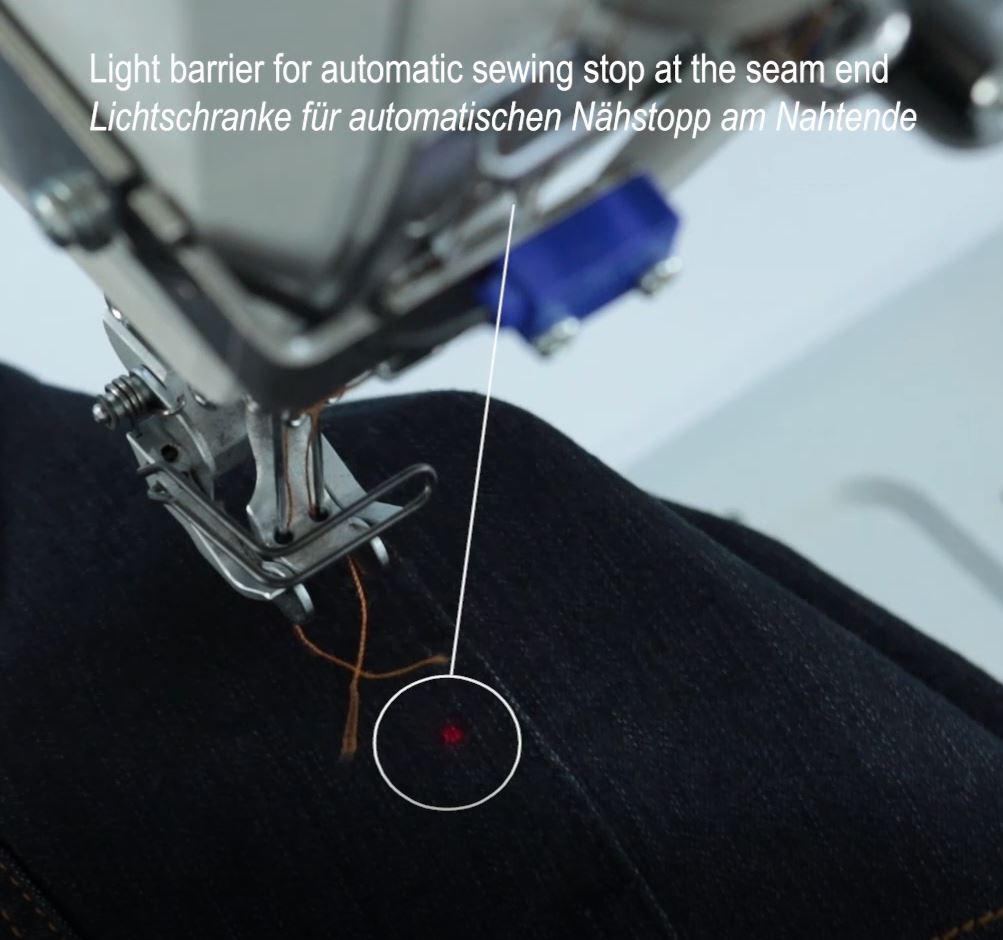

Light Barrier for automatic sewing stop at the seam end

Light Barrier for automatic sewing stop at the seam endLight Barrier for automatic sewing stop at the seam end

Pneumatic additional thread tension for excellent stitch formation when sewing over thick spots

Integrated maintenance indicator

Integrated maintenance indicator Integrated 6-function keypad with ergonomically arranged favourite keyThe extremely high sewing foot lift up to 20 mm max. facilitates the feeding and removing of bulky workpieces

Integrated 6-function keypad with ergonomically arranged favourite keyThe extremely high sewing foot lift up to 20 mm max. facilitates the feeding and removing of bulky workpiecesExamples of use

Workmanship “Sewing start waistband edge”

With this method of operation, a program can be created on the control panel that allows programmed sewing using stitch counting. The 2nd stroke is automatically switched on at the desired points. This ensures efficient working and topstitching seams of equal length.

Sewing start – waist

The support table is optionally equipped with an edge guide. Here the upper edge of the trousers can be placed. The trousers are pulled over the post from behind. Thus thesewing start is always at the right place. The end of the seam is detected by a light barrier (option). This enables highly productive work.

Performance example in 480 min.:

Topstitching of approx. 1,350 – 1,450 pair of jeans (2 seams)

Technical specifications

info

Stitch length1-9

1-9

info

Stitches/min.2.500*

2.500*

info

Sewing MaterialM / MS

M / MS

Single needle

info

Twin needle 3,2/4,8/6,4/7,2/*

Lockstitch (301)

Vertical hook, large (L, Ø 26 mm)

Bottom feed, needle feed and alternating foot top feed

info

Thread trimmer15mm

15mm

info

Seam backtacking A

A

Sewing foot lift, automatic

Stitch count

Reflecting light barrier for automatic sewing stop at fabric end

info

Stroke of the alternating sewing feet9

9

info

Quick stroke adjustment via knee switch and foot stroke adjustable by dialinfo

Integrated 2nd qick stroke adjustmentIntegrated 2nd stitch length adjustment

info

Clearance when Sewing/LiftingA= 10

/

B= 20

A= 10

/

B= 20

info

Additional thread tension,A

A

Program control, operating panel OP1000

Integrated LED sewing light with dimmer

Oil maintenance indicator

info

Air requirement per stroke / Air pressure0,7

/

6

0,7

/

6

info

Needle system134-35

134-35

info

Needle size100-130

100-130

info

Synthetic80/3 - 10/3

80/3 - 10/3

info

Dimensions (Length, Width, Height)1.060

/

600

/

1.700

1.060

/

600

/

1.700

info

Post bed machine with clearanceC=335 / D=297

C=335 / D=297

info

Nominal voltage1x230V, 50/60 Hz

1x230V, 50/60 Hz

info

Rated power375

375

info

Weight, sewing head68

70

Standard

Optional