The top-class high-speed seamers of the 272 series convince of the advantages related to a flexible use, the perfect seam quality and its reliable performance. The state-of-the-art sewing kinematics produces excellent stitch formation even in very fine and extremely lightweight materials. Consistently perfect stitch formation is guaranteed even at maximum speed, with minimum thread tension and lowest thread stress. By means of the thread nipper the needle thread is pulled to the reverse side of the fabric at the seam beginning. This guarantees an always neat seam beginning.

272 | Single needle lockstitch machines with needle feed

The special sewing machines for universal use

Your benefits at a glance

272-140342-01

272-140342-01

272-140342-01 – for universal use

Single needle lockstitch machine with bottom and needle feed, thread trimmer, sewing foot lift, seam backtacking, thread nipper for a neat seam beginning and integrated DC positioning motor incl. operating panel OP1000

Thread clamp

The thread clamp enables a clean seam begin and end. It pulls the thread extensions to the back side of the material. Thus the right fabric side is clean without any thread ends, no thread need to cut on the right fabric side.

272-160362-01

272-160362-01

272-160362-01 – with large horizontal hook (+ 70%) and optionally “TRI-FLEX” device

Standard equipment like 272-140342-01. The optional TRIFLEX device allows calling up two different thread tensions and two different stitch length for a comfortable finishing of jacket / blazer pockets and decorative stitching.

High-quality DÜRKOPP ADLER control technology

High-quality DÜRKOPP ADLER control technology

DÜRKOPP ADLER control technology

The machines are equipped with "DAC classic" control system.

„Plug and Play“ - all machine parameters can be stored in the machine ID and are retained when the control system is changed.

DAC classic control with control panel OP1000

- Electric strength (up to 400 V AC)

- Extended operating range (190 V AC to 250 V AC)

- Updatability via various storage media

- Special energy efficiency by optimum software parameters by means of machine ID technology

- Freely programmable functions and inputs

- Seam programming

Multi-function pushbutton bar for quick access

Ergonomically placed multi-function button for

- Edge trimmer ON/OFF

- seam backtacking

- needle up/down in the seam

- single stitch and backtack inversion

272-640642-01

272-640642-01

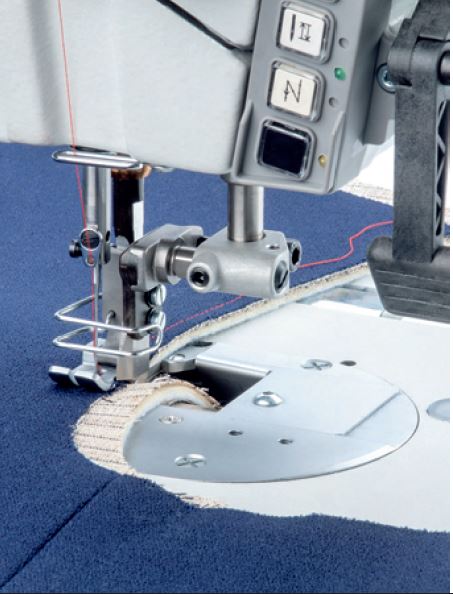

272-640642-01 – with shiftable edge trimmer

Standard equipment like 272-140342-01. The DC coupled edge trimmer is shiftable and lends itself for straight and slightly curved cutting edges.

272-740642-01

272-740642-01

272-740642-01 – with shiftable edge trimmer, driven by electric motor

Standard equipment like 272-140342-01. The edge trimmer driven by electric motor is flexible shiftable and selectable in two different speeds, depending on material quality.

Examples of use

272-740642-01 – Runstitch and trim collars and cuffs

The efficiency of the operation will be obvious increased by using an optional suction device for cutting waste from above or below.

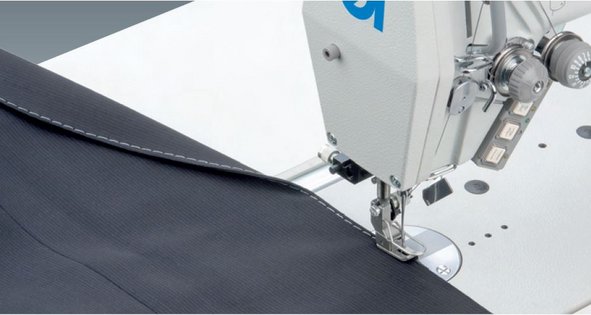

272-140342-01 – Topstitching seams

Perfect topstitching of shirt collars and cuffs can be realized in connection with sewing equipment E70.

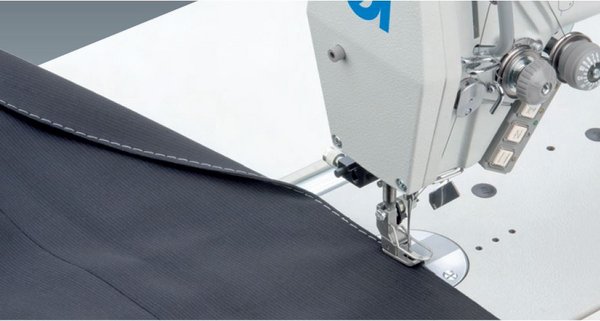

272-140342-01 – French sleeve seams

For high-class shirts in connection with sewing equipment E75 and attachment N471. Performance example: insert and topstitch approx. 180 – 220 pairs of shirt/blouses sleeves (french seam) in 480 min.

272-160362-01 – Finishing outside pockets of men’s jackets (E33, Z116)

Optional "TRI-FLEX" device for sewing, decorative stitching or basting with only one machine; large hook for a bobbin thread capacity increased by 70%; 2 stitch lengths with up to 6 mm stitch length and stitch loosening for basting the pocket opening; stitch loosening can be switched off for decorative stitching. Performance example: Finishing and basting approx. 750 piped pockets in 480 min.

272-160362-01 – Decorative stitching

e.g. at jackets or coats front edges with the optional "TRI-FLEX" device Z116 027201. The 2nd shiftable thread tension enables a perfect stitchformation in change between the lapel edge to front edge.

272-640642-01 / 272-740642-01 – Attaching and simultaneously cutting the chest piece

In the jacket front part with option 0272 590034. The lack of stitch formation in the shoulder area allows the complete cutting of the chest piece. Thus an efficient processing is possible.

272-740642-01 – Runstitch and trim peak lapel and small parts

Performance examples:

approx. 450 – 500 jackets – runstitch and trim peak lapels in 480 min. or approx. 1.200 – 1.400 flaps in 480 min.

272-640642-01 with needle feed andedge trimmer

e.g. for attaching waistbands to trousers with simultaneously cutting the edges.

Technical specifications

info

Stitch length4

6

4

4

info

Stitches/min.5.000

4.000

5.000

5.000

info

Sewing MaterialL / M

M / S

L / M

L / M

Single needle

Lockstitch (301)

Horizontal hook, small (S, Ø 22mm)

Horizontal hook, large (L, Ø 26 mm)

Bottom feed and needle feed

Edge trimmer, DC coupled

Edge trimmer, separately motor-driven

Seam backtacking, sewing foot lift and thread cutting, pedal-controlled

Disable backtacking, needle up/down and intermittent tacking, actuated by hand

Thread nipper for a neat seam beginning

Suction device for cutting waste material

2 stitch lengths / 2 thread tensions

info

Clearance when lifting, electro magnetic8

8

8

8

Program control, operating panel OP1000

info

Air requirement per stroke / Air pressure-

/

-

-

/

-

-

/

-

0,05

/

6

info

Needle system797 (max)

797 (max)

797 (max)

797 (max)

info

Needle size70-120

70-120

70-120

70-120

info

Synthetic30/3

30/3

30/3

30/3

info

Flat bed machine with clearanceC= 285

/

D = 115

C= 285

/

D = 115

C= 285

/

D = 115

C= 285

/

D = 115

info

Nominal voltage1x230V, 50/60 Hz

1x230V, 50/60 Hz

1x230V, 50/60 Hz

1x230V, 50/60 Hz

info

Rated power500

500

500

500

info

Weight, sewing head51

51

51

51

info

Weight, complete58

58

58

58

info

Packaging size (Length, Width, Heigh)780

/

370

/

790

780

/

370

/

790

780

/

370

/

790

780

/

370

/

790

Standard

Optional

Downloads

Operating Instructions

Parameter Lists

272 / DE, EN, IT, ES, PT, FR

Parameter Lists / PDF 397 KB

272

Parameter Lists / PDF 1 MB

272 / EN

Parameter Lists / PDF 644 KB

272 / FR

Parameter Lists / PDF 883 KB

272 / HU

Parameter Lists / PDF 843 KB

272 / PL

Parameter Lists / PDF 866 KB

272 / RO

Parameter Lists / PDF 922 KB

272 / ES

Parameter Lists / PDF 801 KB

272 / DE

Parameter Lists / PDF 664 KB