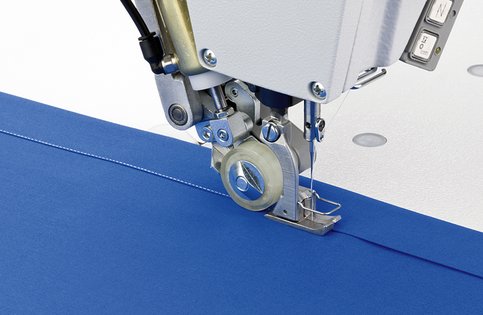

The top puller feed machines 273 and 274 are predestinated for flat seams – even in difficult-to-feed fabrics. Even at maximum speed the top puller feed is characterized by its synchronous working method. Supplementary to the bottom feed the material is systematically tensioned during the sewing process due to the additional intermittently operating puller, thus producing a pucker-free seam. Due to the thread nipper the needle thread is pulled to the reverse side of the fabric at the seam beginning. This guarantees an always neat seam beginning. The machines can very easily be converted to bottom- / needle feed machines by lifting the puller out of the working area by hand.

With the triple feed (bottom, needle, top puller feed) the 274 is predestined for displacement-free seams even in pile fabric like e.g. velvet.