Creating flat seams is the challenge on long seam closing. Manually sewing closing seams is a long training process where the fullness often occurs where we do not need it. In order to counteract the problem, we offer sewing machines that can perform the sewing process safely and automatically.

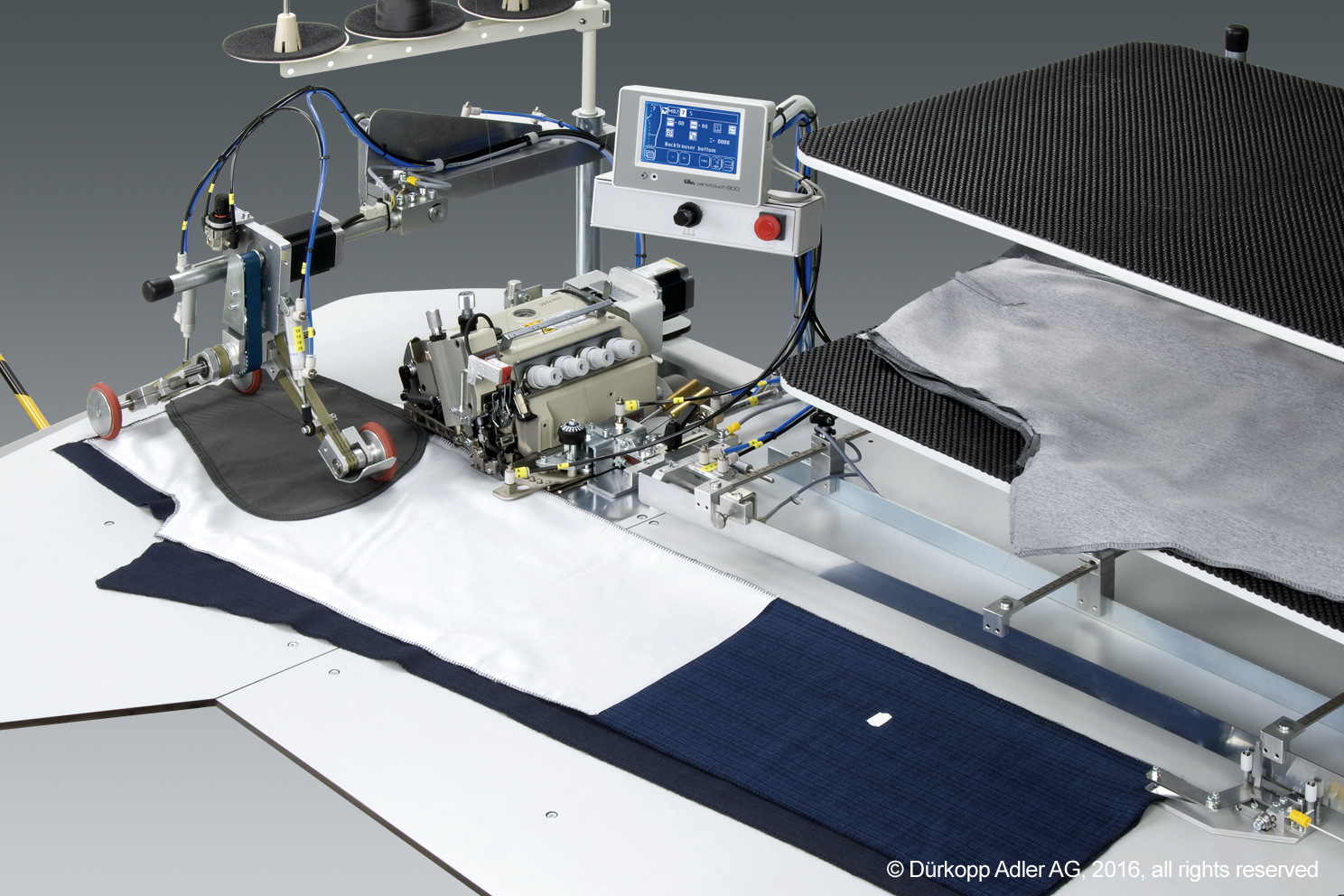

1281 | Sewing unit with pre-laying table for long closing seams

Flat seams - we accept the challenge!

Your benefits at a glance

Flexibility by use of double-chainstitch or 4- / 5-thread safety seams alternatively

Flexibility by use of double-chainstitch or 4- / 5-thread safety seams alternatively

Stitchtype

Alternatively double-chainstitch seams or safety seams with 4 or 5 threads can be sewn. Therefore a change of the sewing equipment is required.

Automatic fullness distribution

The step motor-controlled, progammable fullness distribution (1280 590214)for the differential top and bottom feed allows the programmed recall of different fullness values within a seam.

The pneumaticfullnessdistribution (1280 590204) for the differential top and bottom feed allows the programmed recall of different fullness values within a seam.

Operating panel

- Multi-Touch screen “Commander Pro” with color graphic display for easy programming and quick access to all parameters

- Intuitive and flexible user-interface design

- User tutorials are available in control panel as video and as PDF format

- User guide in control panel is available in 15 languages 200 programs, 40 sequences, max. 14 programs for each sequence can be programmed

Manual sewing

The equipment for manual sewing inthe hip curve section when processing side seam pockets or wing pockets, allows a perfect seam guidance also inthe area of the pockets

Pneumaticedgeguide (1280 590044)

is required in connection with safety seams where the material is to be trimmed, e.g. trimming of pocket bag overhangs in the waist area.

A material waste slide takes care of the removal of the cutting waste. An automatic suction unit for material waste (1280 590554) can be fitted as an option.

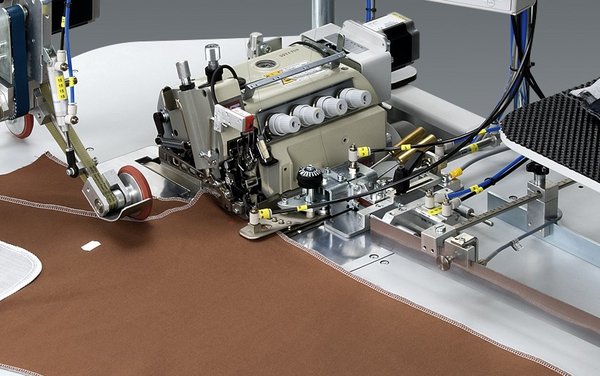

Contour guide

For equal seam widths. The contour guide is equipped with air nozzles to ensure smooth transport of the sewing material.

Photocell

A photocell detects the beginning and the end of the seam and thus ensures that the sewing process runs automatically.

Efficient work due to overlapping working method

Efficient work due to overlapping working method

Overlapped working method

The 1281 comes with a preparation table with mouse and revers device for smooth positioning of sewing parts and for overlapped working method.

DAC Compact - Control technology

with control system and machine ID for saving the machine parameters in the machine ID. Machine parameters are retained when the control system is changed.

The puller ensures an even transport of the sewing material during the sewing process. Afterwards, the roll-out device takes over the material and ensures a safe chain cut and then transports the material into the stacker. The puller with roll-out device is standard on the 1281 and available as an option for the 1280 (1280 590024).

Alternatively, the pneumatic swing out device with down holder is available as an option for 1280 (1280 590714 ). It replaces the down holder, which is mounted in the standard version of the machine. It ensures safe chain cutting and swivels short parts into the stacker.

The thread monitor

indicates a thread breakage and stops the machine. A maximum of 3 thread monitors can be fitted to the machine.

Laser marking light (1280 490154)

is recommended for closing side seams with side seam or wing pockets. It is used for exact positioning of the bartacks in the side seam. The bartack position can be checked before closing the seams and easily corrected if necessary.

Flip stacker 201/6 (1280 590624)

for stacking short to long sewing pieces.

Bundle size: small to medium bundles.

Split stacker (1280 590634)

Splits the left and right trouser parts automatically. It is recommended in case the production process for left and right parts should be continously separated in the production. Or when more capacity is required in the stacker in large bundles.

Clamp stacker with 2 storage racks (1280 590604)

for stacking short to long sewing pieces.

Bundle size: small to large bundles.

Clampstackerwith 3 storageracks (1280 590614)

for extended stacking for long to very long trousers parts. The clamp stacker is adjustable in length at the 3rd storage rack and prevents long trouser parts from lying on the floor, after stacking.

Bundle size: small to large bundles.

Examples of use

Closing side seams

in classic trousers automatically. The equipment for manual sewing in the hip curve section when processing side seam pockets or wing pockets, allows a perfect seam guidance.

Performance in 480min.: approx. 1,350 – 1,500 side seams

Closing side seams

in casual trousers automatically. The equipment for manual sewing in the hip curve section when processing side seam pockets or wing pockets, allows a perfect seam guidance.

Performance in 480min.: approx. 1,350 – 1,500 side seams

Closing sleeve seams

The 1281 can be used to close sleeve seams (without slit) in the outer fabric or lining. The chain stitch ensures smooth seams.

Approx. 2,200 seams in 480 min.

Closing the centre back seam

The 1281 is excellently suited for closing centre back seams (without vent). Due to the differentiable top and bottom feed, it is possible to react flexibly to different materials easily and quickly.

Approx. 2,200 seams in 480 min.

Close skirt seams

Approx. 1,650 – 1,800 skirt side or middle seams

Automatic closing of shoulder and side seams in work gowns, lab gowns and doctors' gowns made easy.

Thanks to the simple creation of programs and sequences, shoulder and side seams in work gowns can be sewn easily and quickly, automatically. Depending on the requirements, the sewing start can be fully automatic via light barrier or via foot pedal. The automatic sequence between shoulder and side seam allows comfortable working without manual program change. The sewing unit can be equipped with safety seams or double-chainstitch seams.

Automatic closing of seams on laundry bags.

Depending on the requirements, the sewing start can be fully automatic via light barrier or via foot pedal. The automatic sequence between the lower and side closing seams on the laundry bag allows convenient working without manual program change. The sewing unit can be equipped with safety seams or double-chainstitch seams.

Technical specifications

info

Stitch length0,5 – 3,5

info

Stitches/min.5.500

info

Sewing MaterialL / M

info

Serging width, selectable9-12

Double chainstitch (401)

Safety seam, 4 threads

Safety seam, 5 threads

Looper (crossline)

Differential bottom feed and variable top feed

Fullness above, flat sewing, fullness below

Reflecting light barrier for automatic sewing start at fabric beginning

Reflecting light barrier for automatic sewing stop at fabric end

Adjustable table height

850-1200

Stacker

Program control, operating panel with graphic display and touch screen

info

Air requirement per stroke / Air pressure20

/

6

info

Needle systemB 27

info

Needle size80-110

info

Bulked thread100-120

info

Nominal voltage1x230V, 50/60 Hz

info

Power consumption

1.0

info

Weight, complete206

info

Packaging size (Length, Width, Heigh)2.300

/

1.500

/

1.750

Standard

Optional