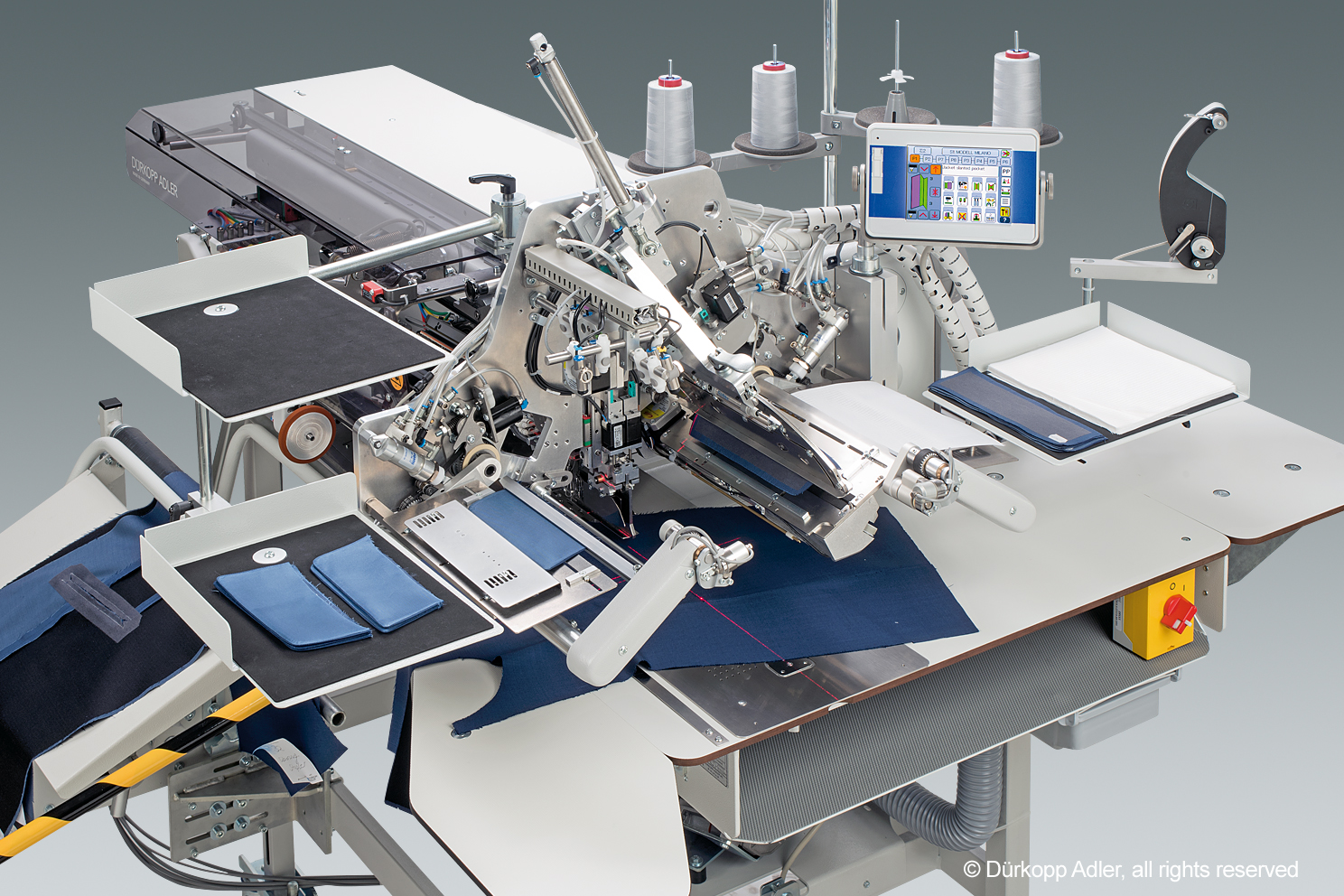

High-performance technologies for pocket openings with fully automatic loading devices

Outer pockets - Breastwelt pockets - Lining pockets

The rational - the special - the comfortable solution, no matter what you are looking for your production, we offer you the most flexible solutions in the piping pocket technology. Highest quality standards and maximum flexibility, combined with the best possible productivity - that is our product. From the standard piped pocket to sophisticated piped pockets with automatic pattern matching, we are at home there.

YOUR BENEFITS AT A GLANCE

Fully automatic feeding methods (depending on the subclass)

Fully automatic feeding methods (depending on the subclass)Programmable needle feed for difficult-to-feed materials

The programmable needle feed improves the seam quality in difficult to-sew materials, e.g. stretch material, patterned material, coats and leather goods. The transport length can be individually adapted to the material and stored in the program. In addition there is a special knit ware mode available.

Manual feeding methods (depending on the subclass)Knitwear mode

Manual feeding methods (depending on the subclass)Knitwear modeSpecial "knitwear mode" for low-tension sewing of piped pockets

Knitwear-mode enables a much better seam quality in knitwear and jersey material - It is included in the programmable needle transport.

Programmable, stepper motor controlled laser marking lamp in longitudinal direction (option 0755 590434) and/or transverse direction (option 0755 590444)

The position of the laser markings can be corrected individually for each program and thus adjusted to different material thicknesses via fine adjustment. The individual, mechanical adjustment of the laser marking lamps in case of model change is eliminated.

Stepper motor controlled transport clamp adjustment with materi al spreading – for e.g. lining or stretch materia

The positions of the transport clamps to the folder sole, are individually and depending on the material, adjustable in the program. This enables the automatic changeover from double to single piping and the program storage to a wide variety of material thicknesses.

Stepper motor controlled center knife drive

With extended flexibility in material use due to adjustable knife stroke height – low knife wear.

Cutting device

The cutting device for needle threads can be adjusted fast and variable. The needle thread catcher for needle distances of 4,8 to 22 mm are available as standard. For needle distances of 22 to 30 mm a further thread catcher is available as an option (0755 350554).

Programmable transport clamp pressure

For different materials such as lining processing with fleece strips and stretch materials.

"Highest precision for corner cuts through automatic or optional multifunctional corner knife station"

Depending on the material all four corner knife cuts can be individually adjusted and stored to the seam and to the seam ends. Knife corrections are possible with different pocket slants and different materials in all directions.

Programmable laser marking lights in longitudinal and transverse direction

The position of the laser markings can be cor rected individually for each program and thus adjusted to different material thicknesses via fine adjustment. The individual, mechanical adjustment of the laser marking lamps in case of model change is eliminated.

Second thread tension ensures optimum stitch formation in the seam and in the bartack

The additional thread tension ensures a perfect seam quality. The tight stitching in the area of the seam start and end leads to a high quality sewing result.

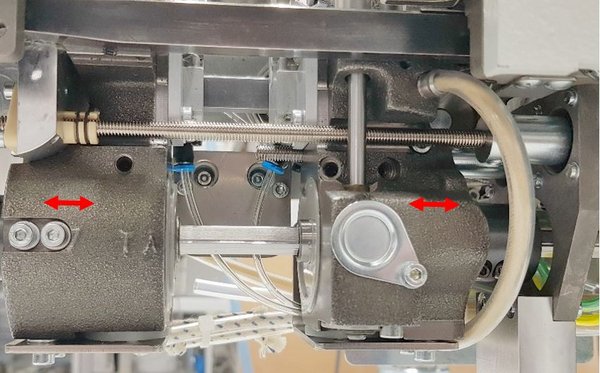

Programmable hook block adjustment

The programmable hook block adjustment allows a quick and automatic adjustment of the left and right hook block after a needle distance change. The hook blocks are moved to the position of the desired needle distance (8.0- 20.0 mm, on the 756 D 10.0 -14.0 mm) by stepper motors. No screws have to be loosened or tightened. This saves up to 15 minutes of conversion time. The programmable hook block setting is recommended for frequent changes of needle distance and is available as special manufacture (for 755/756 A, B, D and F).

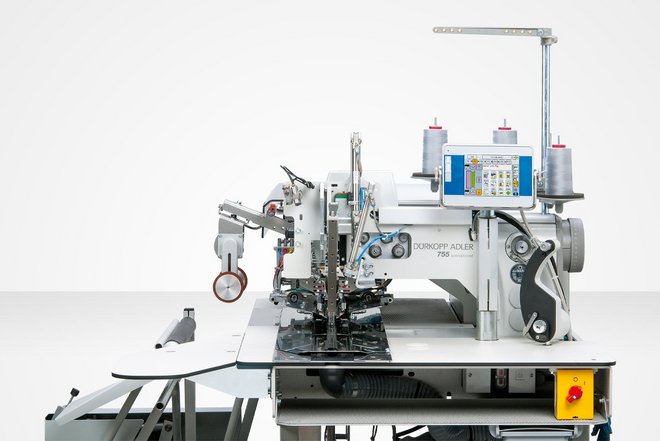

755 A / 756 A | Sewing units for runstitching of straight and slanted piped pockets, flap pockets and welt pockets

Efficient - Flexible - Powerful

Basic machines with strong arguments

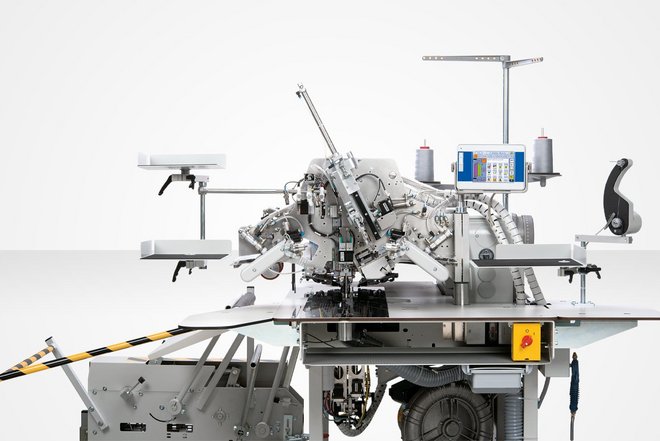

755 B / 756 B | Sewing units for runstitching straight and slanted pocket openings with fully automatic feeding device

Up to 50% time safe in the pocket manufacturing

Powerful technologies for pocket openings

756 D | Sewing unit for breast welt pockets with feeding and matching device for checked or striped breast welts

One for all: Classic - Sporty - Patterned

Bring relaxation to your breast pocket processing

756 F | Sewing unit for runstitching straight and slanted pocket openings with fully automatic feeding device and pattern matching

Up to 20% time safe in the pocket manufacturing

Pattern matching for perfect pocket quality

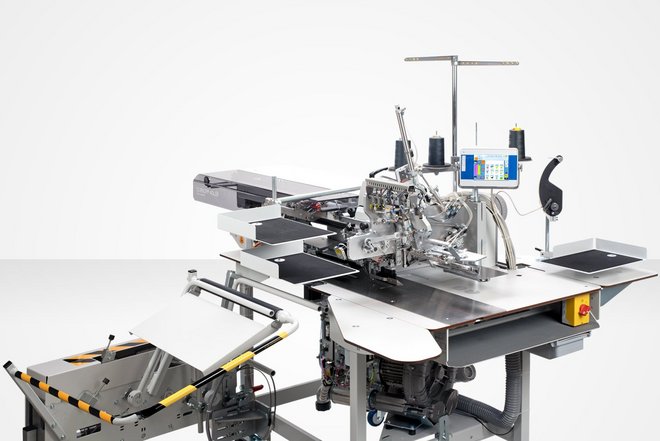

755S | Sewing unit for runstitching of rectangular piped pockets, flap pockets and welt pockets

Innovative and powerful piping technology

The Speedpocket - highest efficiency for fast piping pockets