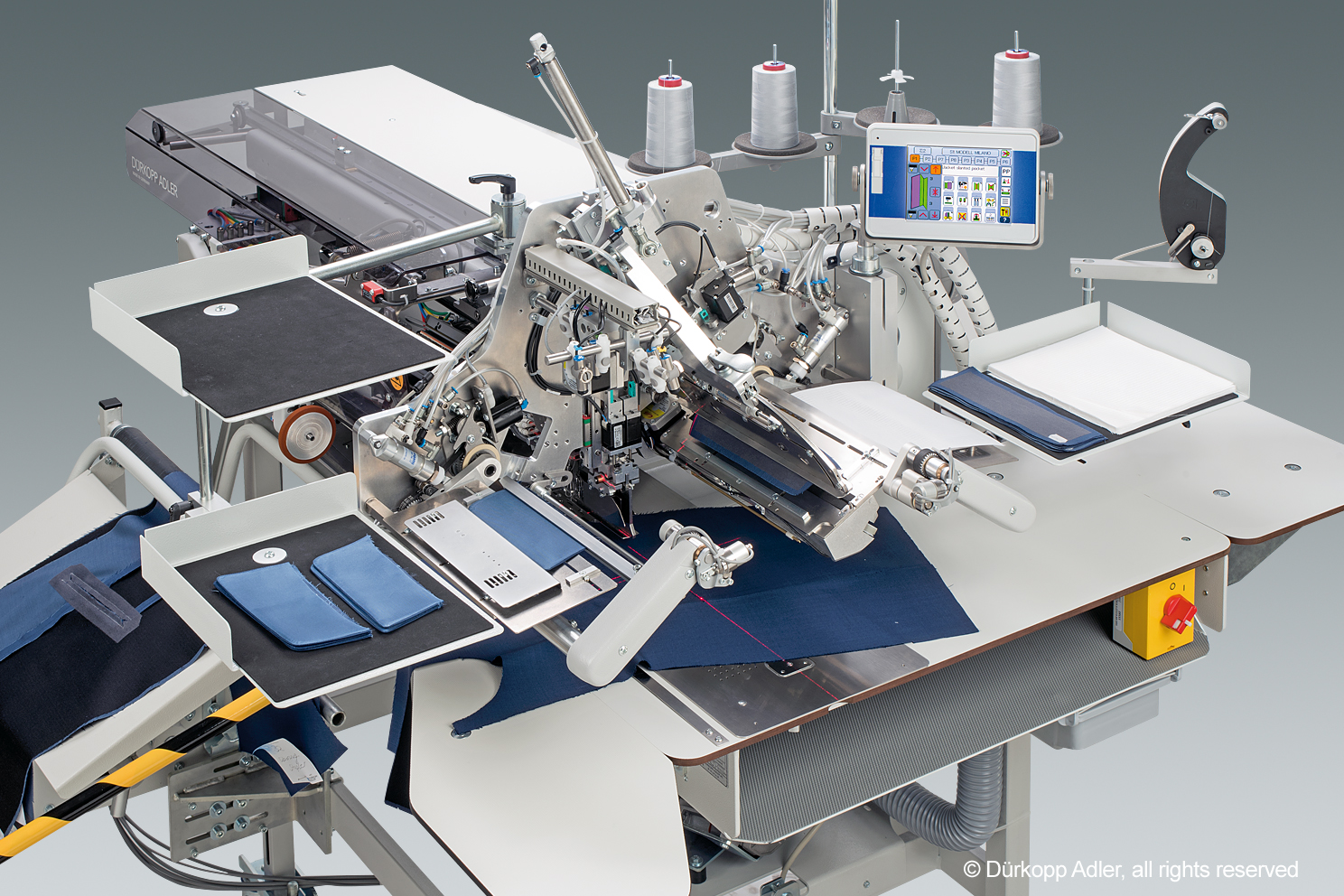

If you want to rationalise the production of your piping pockets, the 755 B and 756 B offers you the best result! With their fully overlapped operation, due to the automatic feeding of the piping strips, they are the ideal solution. The sewing units can also be optionally equipped with automatic feeding of pocket flaps and pocket bags. The automatic cutting device of the piping ends offers a further possible saving of cycle time. Fully equipped, the units can save up to 50% time compared to the manual feeding method. Thus, the sewing units offer the perfect total package to increase machine uptime and reduce handling time.

755 B / 756 B | Sewing units for runstitching straight and slanted pocket openings with fully automatic feeding device

Up to 50% time safe in the pocket manufacturing

Your benefits at a glance

Fully automatic feeding methods

Fully automatic feeding methodsFully automatic feeding methods

With these feeding methods, the piping strips, flaps and pocket bags are fed fully automatically. This method allows a fully overlapped operation when loading the sewing unit. While the sewing unit sews the pocket, the piping ends can already be cut and the pocket components of the following pocket can be loaded and positioned exactly.

Fully automatic piping end cutting

Fully automatic piping end cutting

Fully automatic piping end cutting

Quality improvement and increase in productivity due to the fully automatic piping end cutting: The cutting of the piping ends significantly increases your pocket quality. Marks and shiny spots caused by ironing are visibly reduced with less material layers. In connection with striped fabric, an absolutely exact, pattern correct application of the piping strips is possible. The fully automatic cutting of the piping ends during the sewing process means a time saving of approx. 20% compared to conventional manual cutting with the scissors.

Time saving of up to 50%

Save up to 50% of the production time with the fully automatic feeding of the components and through the automatic cutting of piping ends.

Optimized feeding devices

Allow the operator to load the piping strips onto the support table comfortably and undisturbed. Thus the overlapping working method is much more comfortable and easier to access.

Pocket bag over flap

Pocket bag over flap

Pocket bag over flap

For the processing of jacket outside pockets, we are offering a set of parts „Pocket bag on flap“ (0745 598454) for simultaneous attaching of two pocket bag halves and flap. A special folder enables the flap and pocket bag to be separated and allows the recognition of the flap. This option saves the additional manual attaching of the left pocket bag.

The processing of long pocket bags in conjunction with flaps can also be processed simultaneously on the 756B piped pocket machine. This processing variant offers you approx. 20% savings compared to conventional pocket production.

Performance features (special manufacturing):

- New: additional flap clamps with adjustable stops (SO_23S0008) for simplified application of long pocket bags over flap

- New: pocket bag deflector for safe roll-out of the jacket into the stacker (SO_23S0195)

- New: Programmable flap stop (SO_22S1234) for quick change of flap widths

Unique programmable material adjustment

Unique programmable material adjustment

Unique programmable material adjustment

For easy setting of different material thicknesses by the operator – pocket materials ofdifferent thickness can be processed one after the other without mechanical adjustments. The programming for the height of the folding guide plates (1) and the folder height (2), allow a perfect adaptation to different material thicknesses with only one touch.

Enlarged material passage

The perfected folder system with improved material passage enables the simple and quick exchange of folder and sole inserts in a few minutes.

Programmable hook block adjustment

Programmable hook block adjustment

Programmable hook block adjustment

The programmable hook block adjustment enables fast and automatic adjustment of the left and right hook block after changing the needle distance.

The two hook blocks are automatically released and simultaneously moved by stepper motors to the exact position of the desired new needle distance and locked again. Depending on the method, needle distances between 4.8 and 30 mm can be approached. Thanks to the fast adjustment of the hook blocks (below 1 min.), the complete conversion times of needle distances now only take 15 -20 min. under optimum conditions.

Advantages:

• No loosening / tightening of screws on the hook blocks and bobbin thread knives required

• Great time savings (up to 60 %), for frequently changed needle distances in production

• High flexibility with different pocket widths in the various models

Programmable needle feed for difficult-to-feed materials

The programmable needle feed improves the seam quality in difficult to-sew materials, e.g. stretch material, patterned material, coats and leather goods. The transport length can be individually adapted to the material and stored in the program. In addition there is a special knit ware mode available.

Programmable, stepper motor controlled laser marking lamp in longitudinal direction (option 0755 590434) and/or transverse direction (option 0755 590444)

The position of the laser markings can be corrected individually for each program and thus adjusted to different material thicknesses via fine adjustment. The individual, mechanical adjustment of the laser marking lamps in case of model change is eliminated.

Stepper motor controlled transport clamp adjustment with materi al spreading – for e.g. lining or stretch materia

The positions of the transport clamps to the folder sole, are individually and depending on the material, adjustable in the program. This enables the automatic changeover from double to single piping and the program storage to a wide variety of material thicknesses.

Examples of use

756 B - for straight and slanted pocket openings

Double pipe pockets with flaps in jackets (unicoloured). Additional parts: piping strip, pocket bag (positioned underneath); approx. 1,600 – 2,000 pockets / 480’

755 B - for straight pocket openings

Single- or double piped pockets in hind trousers. Additional parts: piping strip, pocket bag (positioned underneath); approx. 2,000 – 2,400 pockets / 480’

755 B - Trousers pockets

Double pipe pockets with flaps in jackets (unicoloured). Additional parts: piping strip, pocket bag (positioned underneath); approx. 1,600 – 2,000 pockets / 480’

755 B - Lining pockets in jacket / blazer

Single-/double piped pockets in lining

Additional parts: piping strip, 2 pocket bags, lining flap triangle; approx. 1,400 – 1,600 / 480’

Attachment for processing endless zippers

Applications – Trouser pockets, rider pants pockets, jacket lining inner pockets, sportswear clothing etc. for every application special folders are used. With (option 0755 591854) – for tension-free sewing and cutting of endless zippers (with plastic spiral) from the roll. For perfect pocket quality, even in difficult-toprocess materials, the optional "Programmable Needle Feed (0755 160154)" is recommended. Special folders with zipper attachment from the top are available in various types according to needle distances and zipper sizes. They have to be ordered separately (not included in option 0755 591854). Transport gripper for displacement free attaching of the zipper in the seam beginning.

Technical specifications

info

Stitch length0,5-4,5

0,5-4,5

info

Stitch length3.200

3.000

info

Sewing MaterialLM / M / MS

LM / M / MS

info

Seam length20-220

20-220

info

Twin needle8*

8*

info

Twin needle, disengageableLockstitch (301)

Vertical hook, large (L, Ø 26 mm)

Programmable needle transport

Clamp adjustment with material spreading

Thread trimmer, automatic

Automatic corner knive station for straight pockets, freely programmable in the pocket length

info

Automatic corner knife station for straight or slanted pocketsinfo

Multi function corner knife station for straight or slanted pocketsCentre knife with counter knife, separately motor driven

Notching of piping ends

Automatic feeding of piping strips

Automatic feeding of flaps and additional parts

info

Stitch condensing, automaticNeedle thread monitor

Bobbin thread monitor

Bobbin thread control

Suction device for the exact positioning of the fabric

Flip stacker

Bundle clamp with rest table

Program control, operating panel OP7000 with graphic display and touch screen

info

Air requirement per stroke / Air pressure6

/

6

6

/

6

info

Needle system134-35/DPX and others

134-35/DPX and others

info

Needle size80-110

80-110

info

Nominal voltage1x230V, 50/60 Hz

1x230V, 50/60 Hz

info

Rated power500

500

info

Weight, sewing head220

220

info

Weight, complete320

320

info

Packaging size (Length, Width, Heigh)1.830

/

1.230

/

1.590

1.830

/

1.230

/

1.590

Standard

Optional