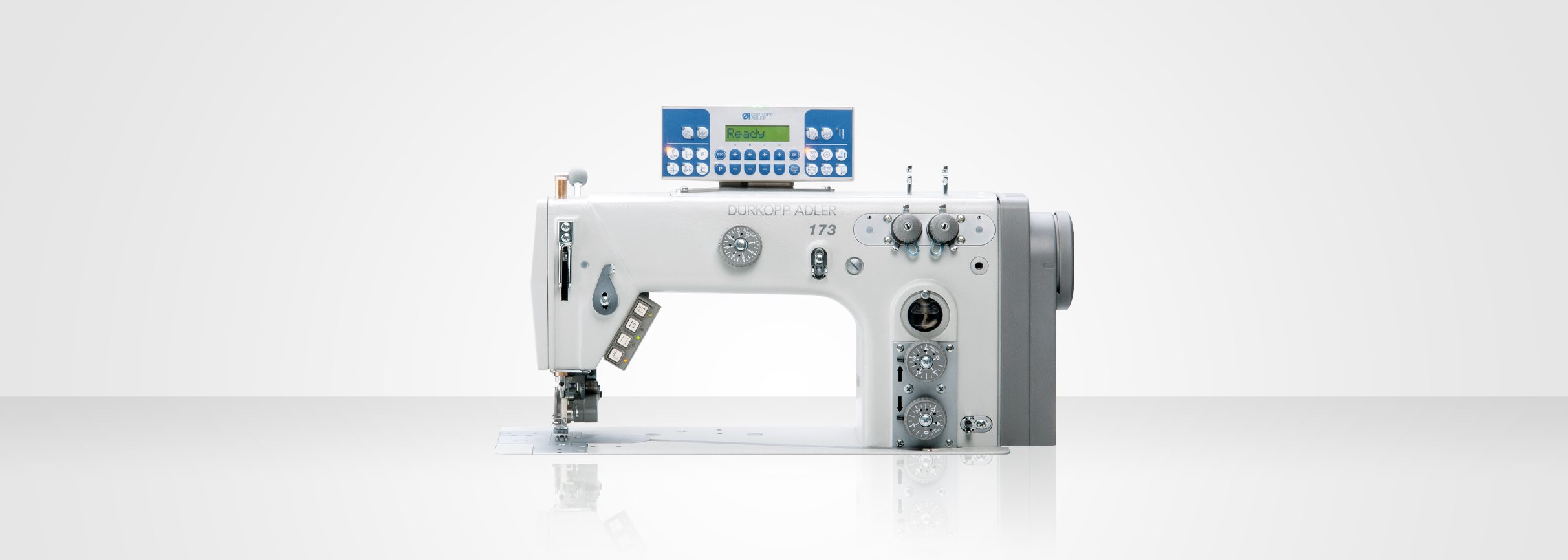

The 171 fulfills all requirements that a rational production philosophy places on a high-performance machine. The optimized sewing kinematics guarantee constant sewing resultswith a wide range of materials. The 173 is predestined for the rational processing of transport-critical goods. This high-performance machine ensures smooth, stress-free seams even in microfibre fabric. The puller feed is absolutely stable even at high speeds.

171 / 173 | Single or double needle chainstitch machine with bottom feed and with/without puller feed

Temperamental and comfortable

Your benefits at a glance

171-131610

171-131610

171-131610

Single needle double chainstitch machine with bottom feed and DAC eco+ control; without thread trimmer; suitable for light to medium weight fabrics

171-141621

171-141621

171-141621

Single needle double chainstitch machine with bottom feed, electro-pneumatic thread trimmer, foot lift, stitch condensing and DAC classic control in combination with panel OP1000; suitable for light to medium weight fabrics

High sewing speed

171: The bottom feed machines have a max. sewing speed of 6,600 stitches/min.

173: The speed-stable top puller feed operates at up to 6,000 stitches/min.

Conversion to two-needle machine

With the conversion set 175-590074, a simple conversion from single-needle to two-needle is possible. Needle distances up to 15mm can be converted.

Possible applications for this:

171-131610 E208/0,4: Closing seat or side seams on classic pants. The needle distance is 0.4 mm.

Parts set 550-2-2 (0550 590344): The designed workstation sews continuous zippers onto fly pieces. The sewing head, which has been converted into a two-needle machine, is equipped with a needle distance of 5 mm.

And many more…

DÜRKOPP ADLER control technology

The 171-131610 and 173-141610 are equipped with the “DAC eco+” control system.

The 171-141621 and 173-141621 are equipped with "DAC classic" control system.

„Plug and Play“ - all machine parameters can be stored in the machine ID and are retained when the control system is changed.

DAC eco+ control (controlpanel in carton)

DAC classic control with control panel OP1000

- Electric strength (up to 400 V AC)

- Extended operating range (190 V AC to 250 V AC)

- Updatability via various storage media

- Special energy efficiency by optimum software parameters by means of machine ID technology

- Freely programmable functions and inputs

- Seam programming

173-141610

173-141610

173-141610

Single needle double chainstitch machine with bottom feed, intermitted working puller feed and DAC eco+ control; without thread trimmer, suitable for light to medium weight fabrics

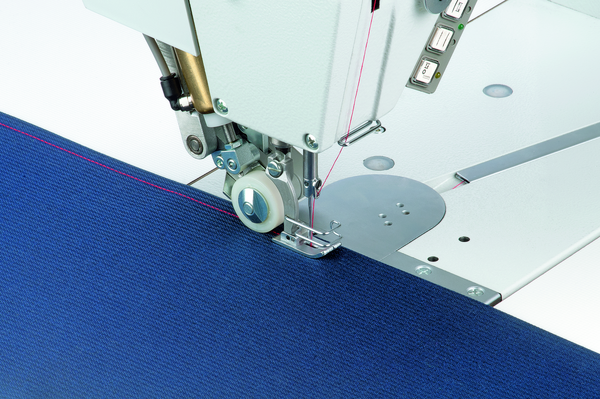

173 – Your advantages:

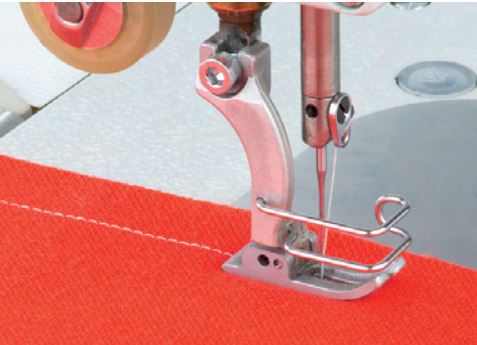

The top puller feed with up to 6.000 stitches/min. runs constantly and works effective extremely close behind the needle.

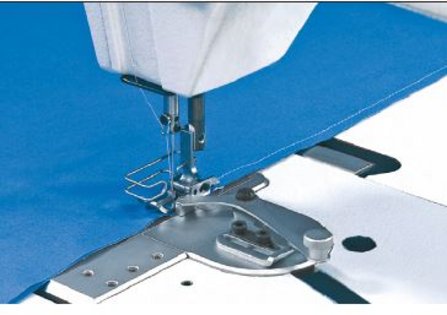

The top puller feed can be swiveled upwards – unrestricted clearance like class 171.

173-141621

173-141621

173-141621

Single needle double chainstitch machine with bottom feed, intermitted working puller feed, electro-pneumatic thread trimmer, foot lifting, stitch condensing and DAC classic control in combination with panel OP1000, suitable for light to medium weight fabrics

The puller feed allows by its small distance from the roller to the needle, a perfect seam quality for smooth seams. For seams, in which do not require puller feed, the puller is swivellable and allows a usable clearance as with the 171

Examples of use

General operations in different areas of the garment industry.

General operations – in particular long, smooth and also elastic seams

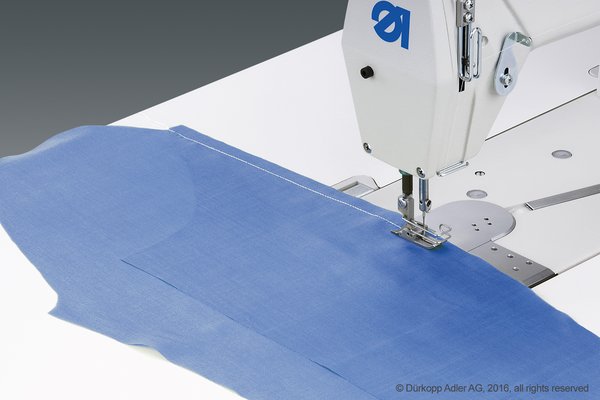

Operations in jacket and blazer manufacturing – closing seams in lining and upper fabric

Jacket and blazer manufacturing

Operations in jacket and blazer manufacturing – closing seams in lining and upper fabric.

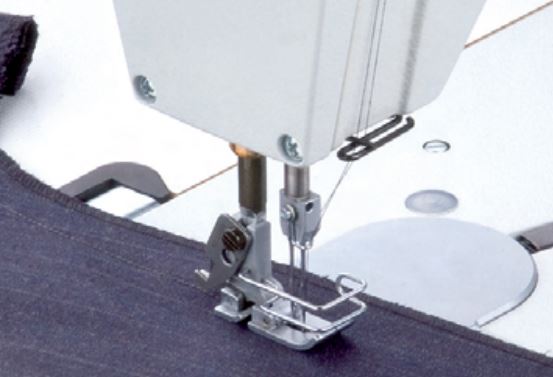

171-131610 E208/0,4

Close seat seams in trousers with tandem sewing equipment – the tandem foot compensates the different fabric heights during the sewing process. The needle distance is 0.4 mm. Due to the two-needle closing seam, an extremely strong and yet smooth seam is created.

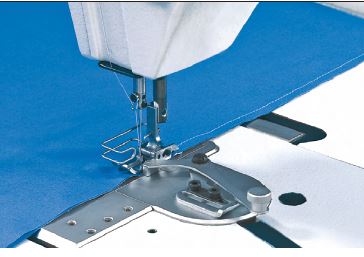

Topstitching of trousers side seams with special edge guide from the bottom (N900 002631), swivable from right to left; for guiding the seam edge (in conjunction with sewing equipment 173 E8).

Set of parts 550-2-2 (0550 590344)

The optimized workstation sews endless zippers on the flies perfectly. The zipper pull-off device ensures the tension-free attaching of the zipper. Depending on the processing method, a non-woven tape can be additionally carried along from below. The sewing head is converted into a double needle machine and is equipped with a needle distance of 5 mm.

Set of parts 550-15-15 (0550 590334 + 0550 400224)

Optimized workstation for sewing and top stitching of shirt back yokes: In one operation, the outer back yoke is inserted by a special attachment and topstitched together with the inner yoke and the back part. The left-hand arranged bundle clamp with rack table allows the operation flow in the waterfall principle.

171-131610 - Attaching and simultaneous pinking of the pants crotch piece

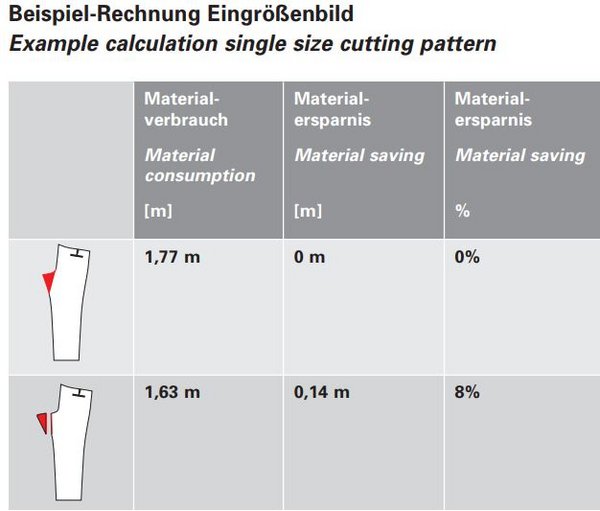

A grown on trousers crotch piece consumes a lot of space in the cutting pattern. Space-saving nesting of the parts is barely possible. It comes to an increased material consumption.

In order to save material and to optimize the cutting pattern, it is recommended to change the back trousers pattern and separate the crotch piece. Thus, the cutting pattern can be planned efficiently. In the workshop, the crotch piece can be sewn and pinked with the part set 550-121 in a high quality.

Output:

- 2,000 trouser crotch wedges / 480' max.

Example of a lower material utilization in a single size cutting pattern due to the grown on crotch piece (1.77 m material consumption each pair of trousers and size).

Example of an optimum material utilization through separated crotch piece (1.63 m material consumption each pair of trousers and size = 8% material saving).

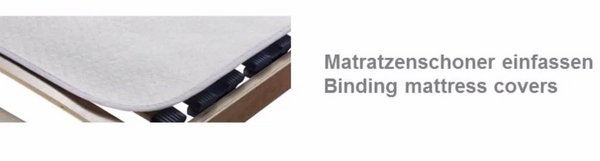

173 - Binding mattress protectors

Another interesting process on the 173 is the binding of mattress protectors, sunshades or household articles. A special version of the machine is equipped with a binder, automatic tape feeding and automatic tape cutting. A light barrier detects the end of the seam and the machine stops automatically to turn the sewing piece manually. If the thread cutter of the machine is actuated, the tape is automatically cut and sewn.

Technical specifications

info

Stitch length4,0

/

-

4,0

/

-

4,0

/

7,0

4,0

/

7,0

info

Stitches/min.6.600

6.000

6.000

6.000

info

Stitches/Min. (ex works)6.000

5.800

5.800

5.800

info

Sewing MaterialL / M

L / M

L / M

L / M

Single needle

info

Twin needleDouble chainstitch (401)

Looper (crossline)

Bottom feed

Bottom feed and top puller feed

Thread trimmer

Hook knife

Sewing foot lift, automatic

Stitch condensinging and sewing foot lift, pedal controlled

Automatic functions, activated by light barrier

info

Clearance when Sewing/LiftingA= 4

/

B= 10

A= 4

/

B= 9

A= 4

/

B= 9

A= 4

/

B= 9

Program control, operating panel OP1000

info

Air requirement per stroke / Air pressure-

/

-

0,1

/

6

-

/

-

0,1

/

6

info

Needle system934

934

934

934

info

Needle size80-130

80-130

80-130

80-130

info

Synthetic70/3

70/3

70/3

70/3

info

Nominal voltage1x230V, 50/60 Hz

1x230V, 50/60 Hz

1x230V, 50/60 Hz

1x230V, 50/60 Hz

info

Rated power500

500

500

500

info

Weight, sewing head37

37

39

40

info

Weight, complete54

54

55

55

info

Packaging size (Length, Width, Heigh)780

/

370

/

790

780

/

370

/

790

780

/

370

/

790

780

/

370

/

790

Standard

Optional